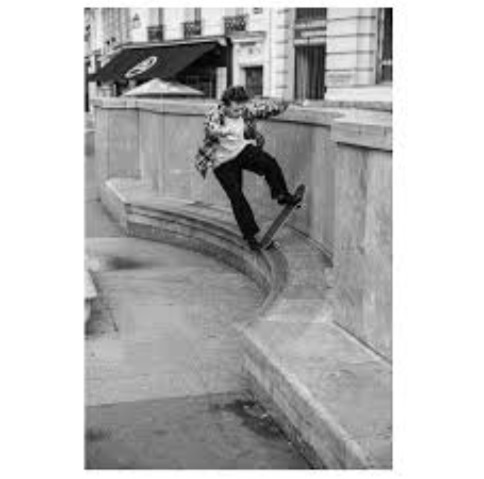

Inspiration

People do tricks on ledges.

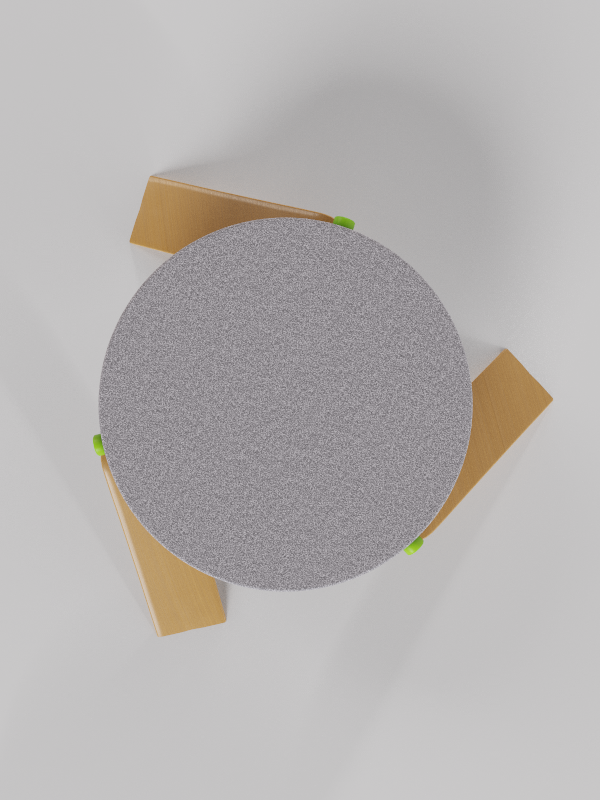

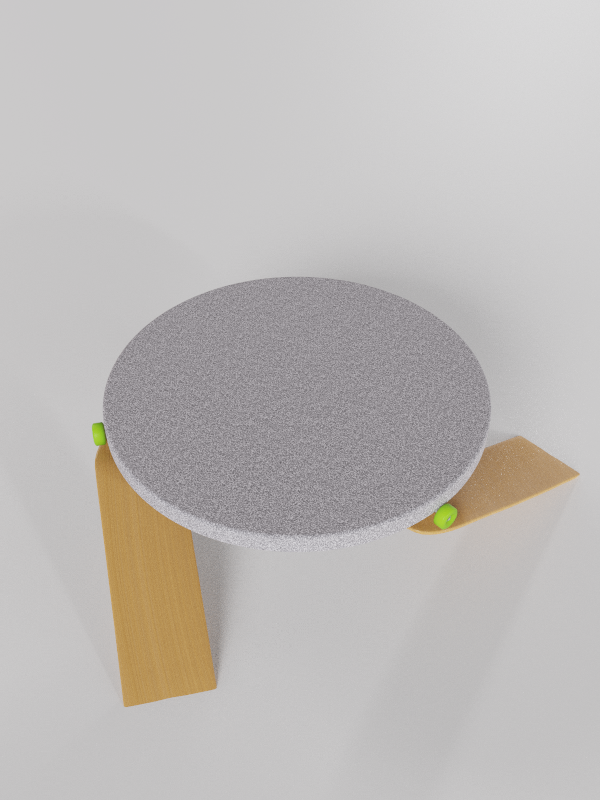

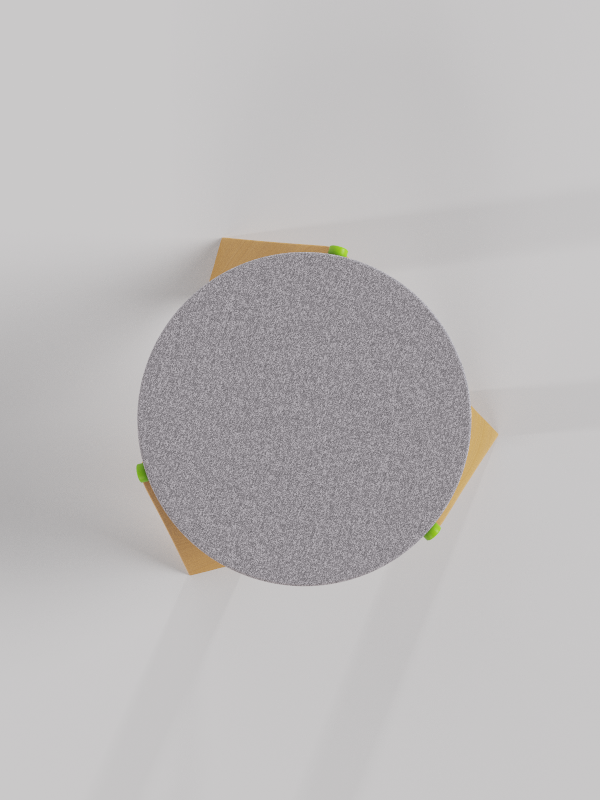

What if I view it as a upside-down way?

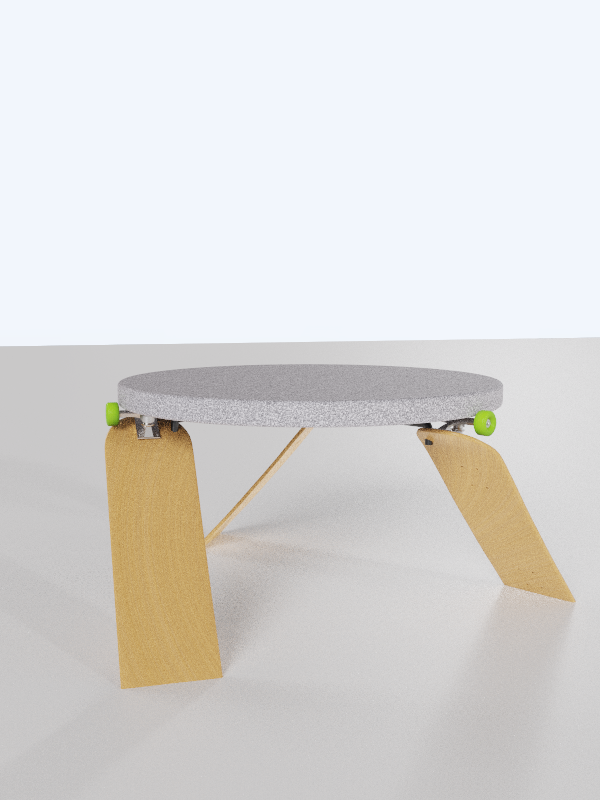

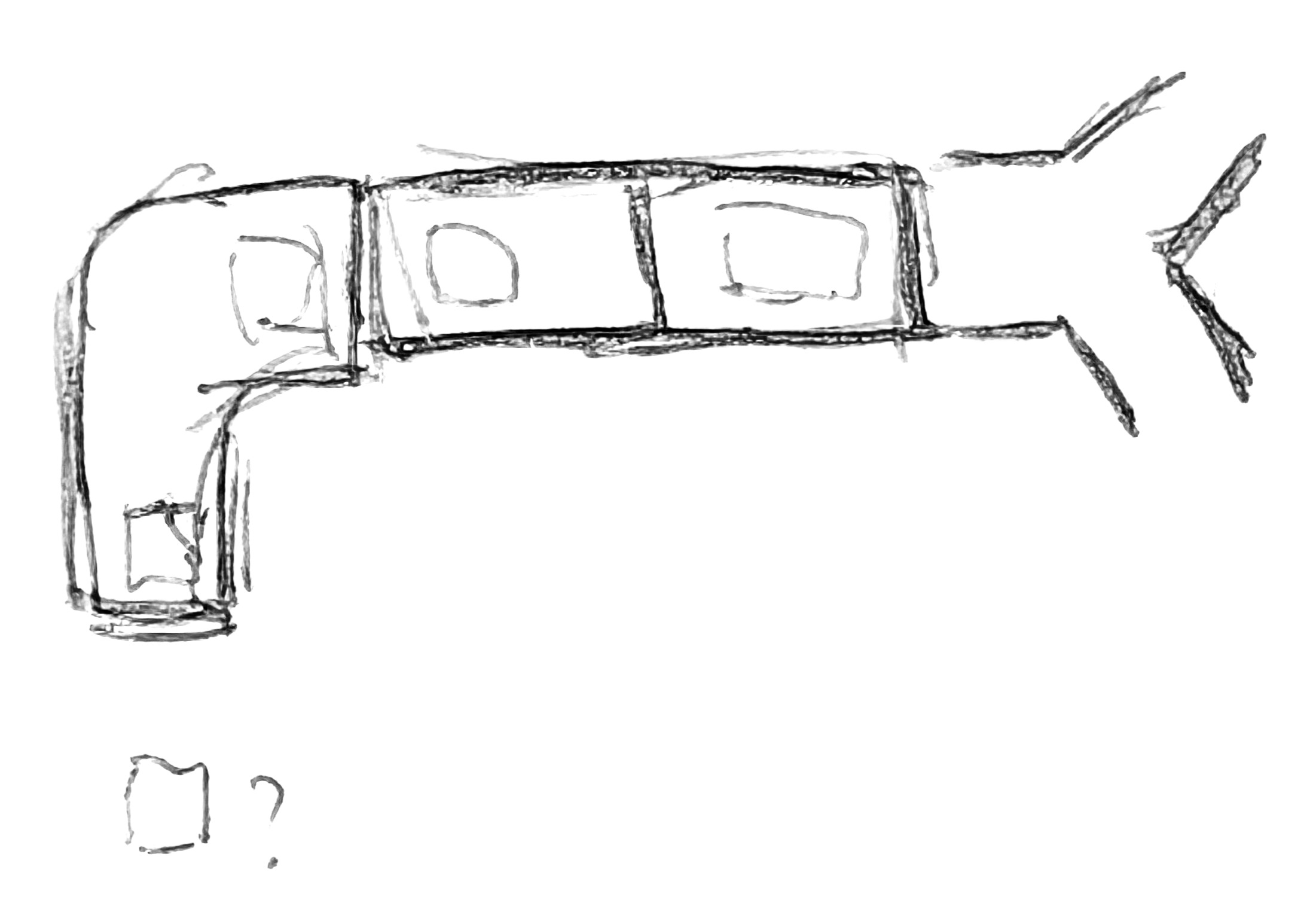

My idea was simple at first, but this combination didn't fit the actual direction of the moves, and it would take up a lot of space, so I changed the direction of the skateboard to improve it.

My idea was simple at first, but this combination didn't fit the actual direction of the moves, and it would take up a lot of space, so I changed the direction of the skateboard to improve it.

The ledges in skatepark used to be concrete or marble. I can apply it to the furniture.

17/10/2024

When making a 3D model, I found that the height of the table can be adjusted by changing the angle. But this will also increase the floor space of the table.

21/10/2024

I made a small prototype first, first to see the effect, and second to see what problems will arise when making the entity later.

22/10/24

When I sanding the deck, I found that the scratching which training naturally leaves is very charming. Training will press the deck to leave scratching and those aera are lower than the original level, so when I sand it, the groves will keep the pattern of deck. It looks like the scratching paper. I feel like I can keep some scratching to make it more fun and corresponding to the topic.

When I polish it, I found that the original wood texture would come out. It is amazing to see the combination of artificial texture and natural texture just like I did in Decks Chair.

23/10/24

I tried to make the tension table with decks. I succussed with structure. But I found it didn't correspond to my topic anymore. It is too complicated and the strings have no meanings only for function and very eye-catching. Compared to my previous plan. The metal bars were hidden under the tabletop, it has very low presence.

30/10/24

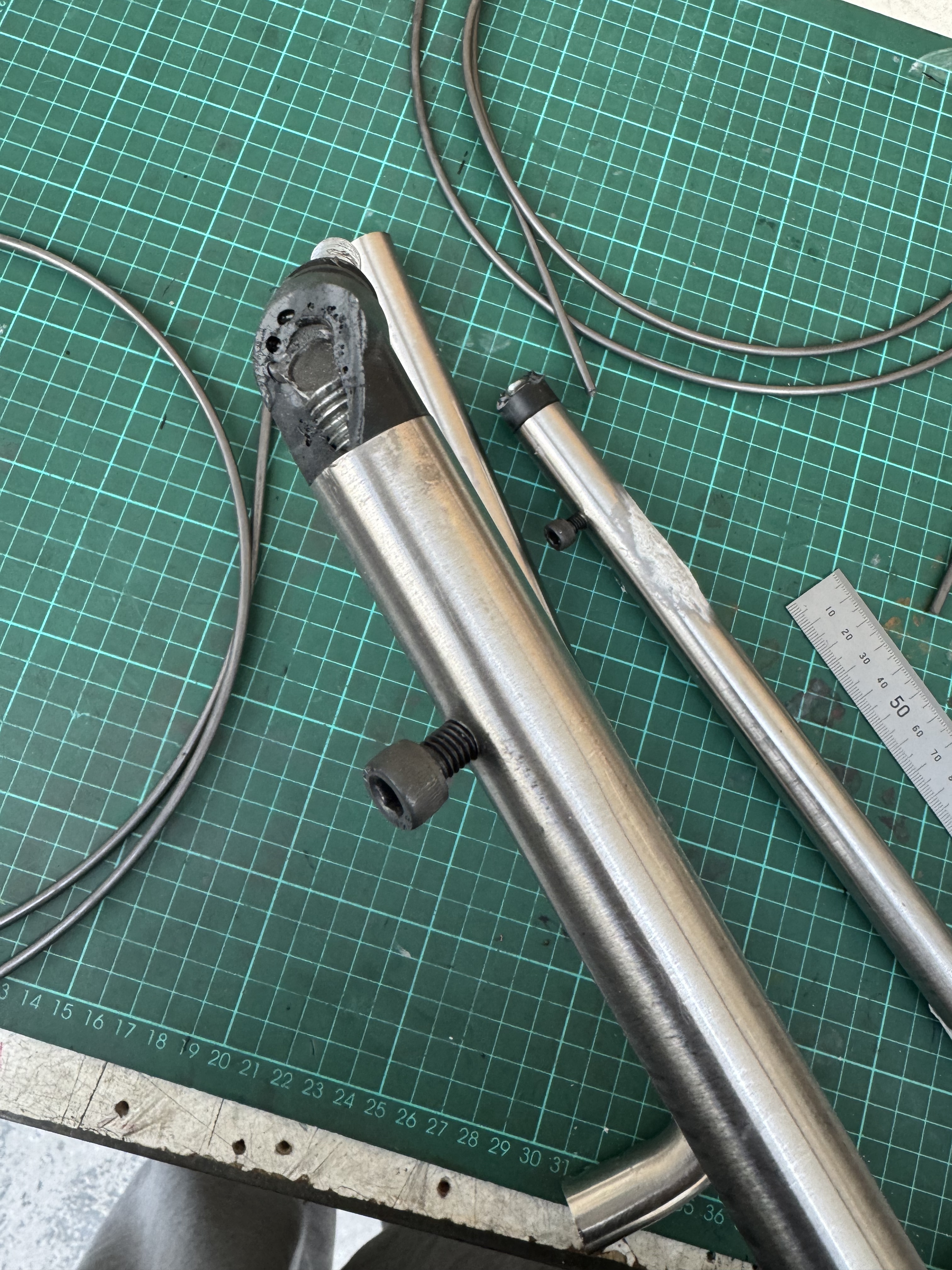

For connection of tube, I bought three key parts. The first one is Y connector, the second is connector nut and the third is 90 elbow.

Because there is no ideal part sold in market, so I have to process them by myself. The Y connector and connector nut is really smooth. But the elbow is not. I found really hard to grind it and I would grind the textured area which shouldn't be grinded. Oscar suggested me use the lath to process it, I will give it a try.

01/11/24

I sanded it with 320 sandpaper and paint it with satin black. The outcome is quite good but I did not pait it evenly because I put it on the box and spray it. I think I should find a way to better paint it.

04/11/24

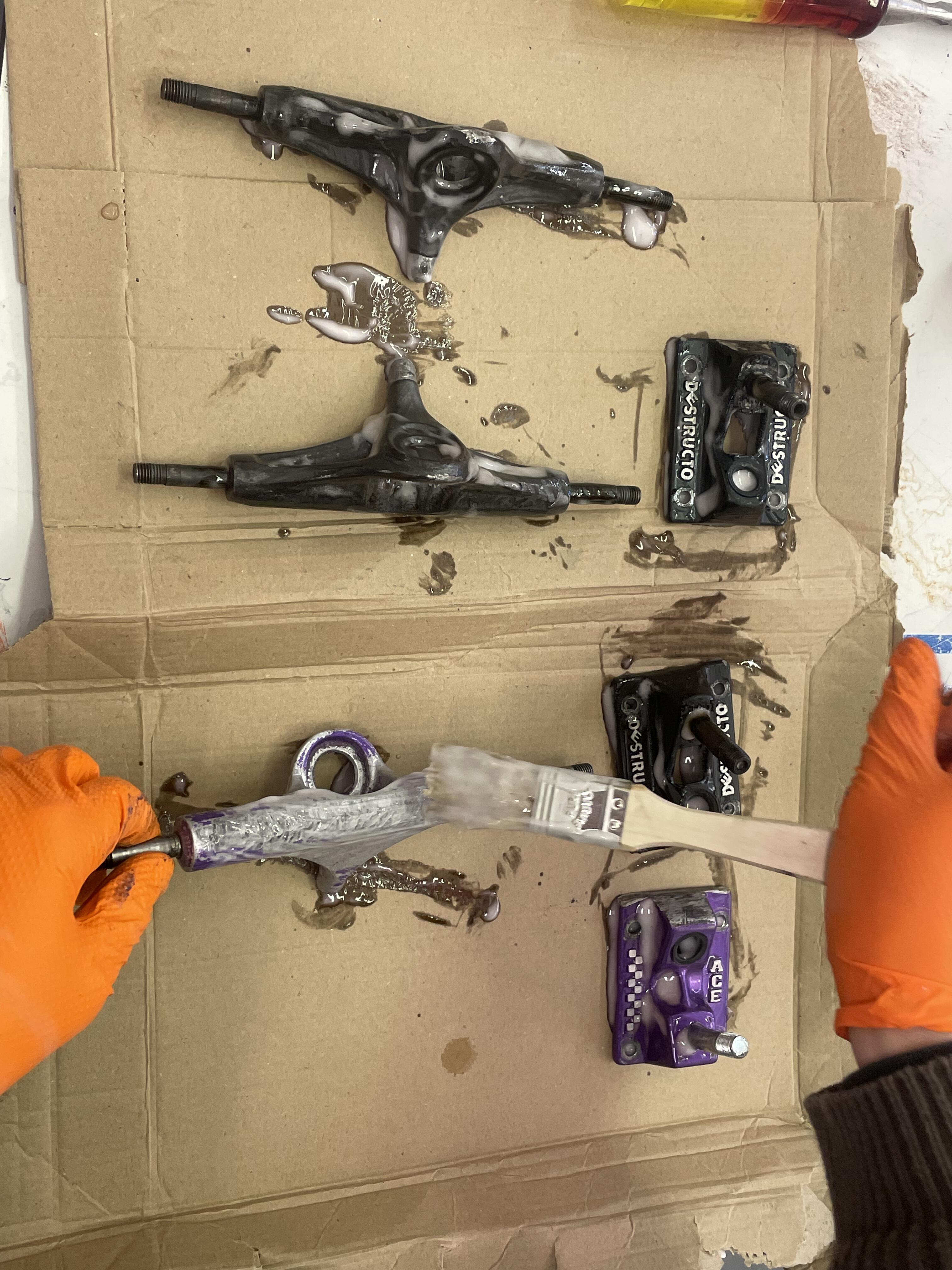

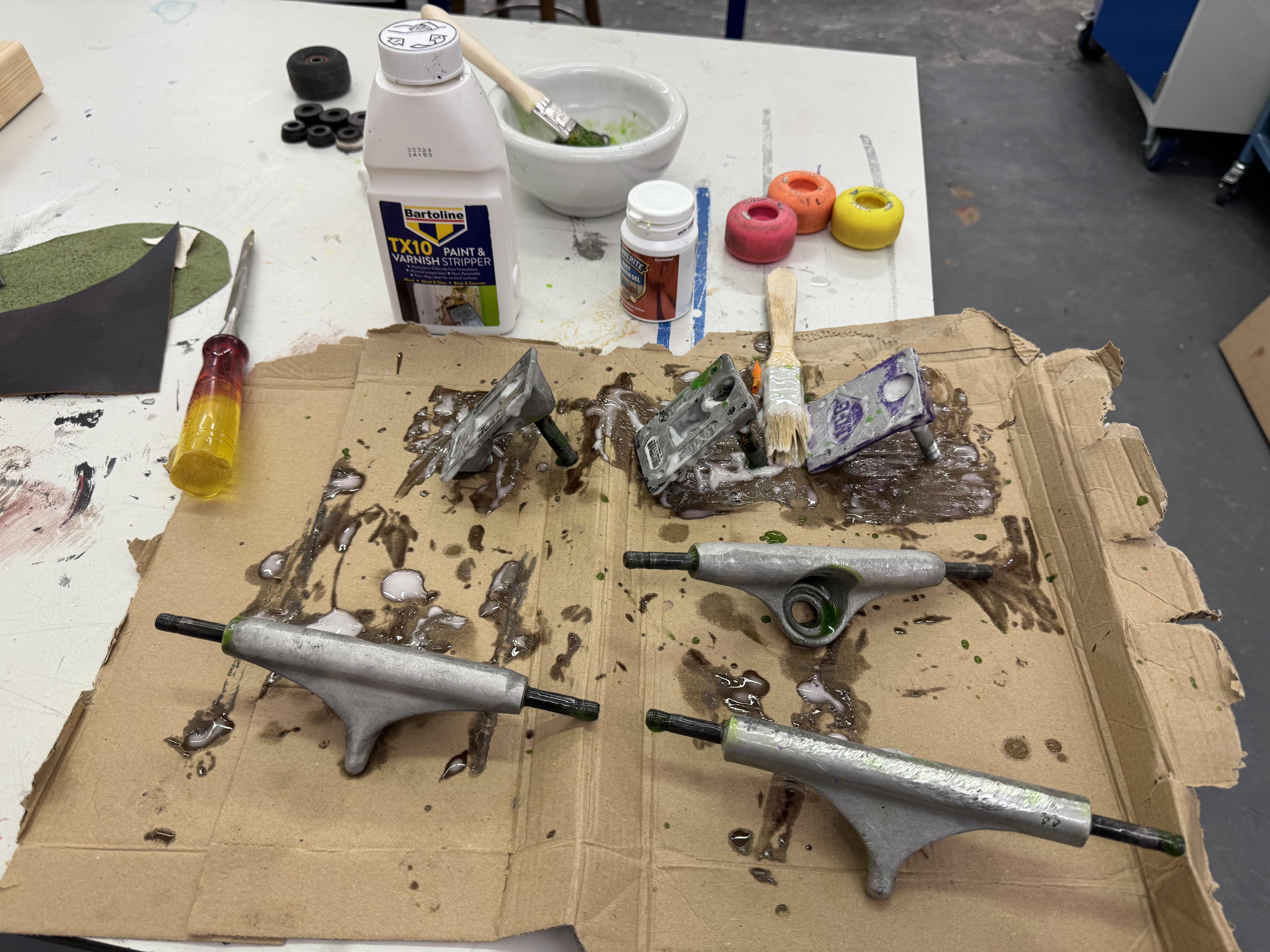

I used the paint stripper and rust remover to renew the trucks. Paint stripper works really good. The rust remover is not. I found that I couldm't leave rust remover on it for a long time because it would even cause more rust. Or maybe this liquid is not so fit to my thing.

05/11/24

Coincidentally I have a wheel with the colors of each deck. This makes the piece more harmonious overall.

08/11/2024

The metal workshop didn't have a lathe. The original plan to process the connector was scrapped. Later, when I saw the door handle, I thought that maybe there were special bending pipes for sale, which would be much more convenient.

I tried to use the connector nut inside to make the connection, but then I found that this method would rotate after installation, so I had to weld the elbow and the straight steel pipe.

Seeing these abandoned chairs, I thought, maybe next time when I need this kind of bending material, I can disassemble the ready-made ones from these chairs.

12/11/2024

After I solved the rotation problem, I didn't expect that the connection was not strong enough. I still had to use welding to make it firm. I thought about why I wasted so much time on this connection. I could have just used welding at the beginning, but I took such a long detour. First, I don't know how to weld, so I want to use other methods instead. Second, I hope that the best situation is that users can DIY such works by themselves, that is, they can do it without these larger machines. In the previous production process, I only used an angle grinder and a hammer. Third, during the installation process, it is convenient to adjust the angle and the height of the table. But this also has certain problems. For example, the bolts near the triangular connection will damage the internal threads, and the friction will also decrease after long-term use, so the best way is to fix the angle and use welding.

In order to weld the three tubes and keep them all at the same angle, I thought of the method in Figure 1, which is to put the steel tube against an object and keep the same distance between them and mark the points. Paste my 120-degree paper template at the mark, and then cut and weld. But then I found that when I pasted the paper template, the angle would actually decrease because of the folding. Next time I should put the angle paper template at the bottom and mark on both sides.

In order to weld the three tubes and keep them all at the same angle, I thought of the method in Figure 1, which is to put the steel tube against an object and keep the same distance between them and mark the points. Paste my 120-degree paper template at the mark, and then cut and weld. But then I found that when I pasted the paper template, the angle would actually decrease because of the folding. Next time I should put the angle paper template at the bottom and mark on both sides.I also discovered the skills of welding during this production. Electric welding is actually performed when the current passes through the welding head and the object. Therefore, I must wear insulating and heat-insulating gloves when welding. The length of the welding head should be kept at about 2cm. If it is too long, the heat will not be enough and the solder will fly out.

15/11/2024

After the strength test was successful, I further improved the length of the plate and the angle of the steel pipe. Finally, I filled the holes with putty where the welding was not good, polished and painted. During the painting process, I found that I had to spray it several times to make it even and without dripping.